TECHNOLOGY

什麼是奈米壓印?

奈米壓印 Nano Imprint Lithography (NIL) 是一種表面處理工藝,其主要是做微結構的形狀複製轉移,

可以分為 UV NIL (光固化)與 Embossing NIL(熱成型),因為 UV NIL 具有低成本、高產出、高解析且適用於多種基材,故鼎力光學選擇以 UV NIL為主力製程。

其製程特色為:

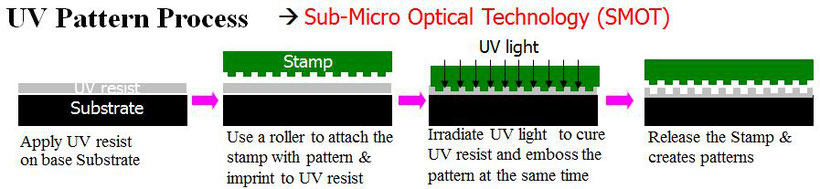

a. 依選用基材材質,在平面基板上提供UV 樹脂後,利用壓印模仁直接壓印與照射UV光固化樹脂,然後將模仁離型即完成 NIL 製程,此工藝可以重複複製模仁上的紋理於欲加工的基材上,得到外觀一致性的UV NIL壓紋產品

b. NIL是環保製程,使用UV燈照射固化取代一般的烘烤作業 ; 同時使用無溶劑UV樹脂減少溶劑排放。

Nanoimprint lithography (NIL) can be categorized into two kinds, UV NIL and Embossing NIL. The reason why Teamlead Optical (TLO) chose UV NIL for manufacturing is that it is a high volume and cost-effective patterning technique. Also, many kinds of substrates can be used and various performances can be shown with high precision (resolution) and high yields at a low cost.

Features:

UV resist applications depend on substrates. The pattern is easily stamped to UV resist coated on a substrate by UV light exposure. When the stamp is removed, the resist pattern can be used for further process. As the picture below, we can repeat stamping to produce the same pattern.

NIL is a sustainable process. Instead of experiencing the heating process and using chemical liquid, patterns are created under UV exposure without the risk of contamination.

什麼是CMF?

過去ID 產品設計師專注於提出新穎創新的設計,讓產品有良好的外觀效果。不過當產品要製作時,可能無法順利量產,或者只能產出模型,而無能力使用真實的材料製作。

所以這些年,所有品牌廠都設立 CMF單位,期望藉由此專業人才去建置CMF系統與提升產品設計的等級。

C : Color 為色彩

M: Material 為材料

F : Finish 為表面處理工藝

所有的產品設計都離不開上述三項的選擇,不同的疊構順序也會產生外觀差異。經由資深或垮領域的人才將ID的設計圖,經過解析去確認合適的工藝、材料、加工方式。避免徒有好的設計圖,卻發生無法製作出成品的窘境。

NIL與CMF的關係

常態的工業產品製作已經非常成熟穩定,除非因為特殊環境要求,例如: 油性塗料改水性塗料、降低有機溶劑使用量、降低耗能製程,不然,會轉換加工技術與材料。但是任何一個變動,都是極大的挑戰。

大家所知的加工廠其加工的想法、做法、製程、設備都類似,所以當ID提出一個載明的CMF需求時,可以預期大家產出的效果會類似,甚至遇到的問題也一樣。這樣的情形,產品要如何做出差異化,新穎性?

雖然NIL只是一道製程工藝,但是其帶來得效果超乎想像

a. 適用多種材料 >>> 任何材料,只要調配好對應的UV膠即可使用。

b. 穩定提供多種紋理 >>> 就像射出模具一樣,重複的複製紋理在材料表面。

c. 變化多樣性 >>> 內紋理/外文理、金屬感、觸感、透明感。

d. 更環保 >>> 不需要濕製程、蝕刻製程、噴砂製程。

e. 具信賴性 >>> 一定程度的硬度、耐磨、耐化性。

NIL可以加工於那些材料上?

現行可以加工材料

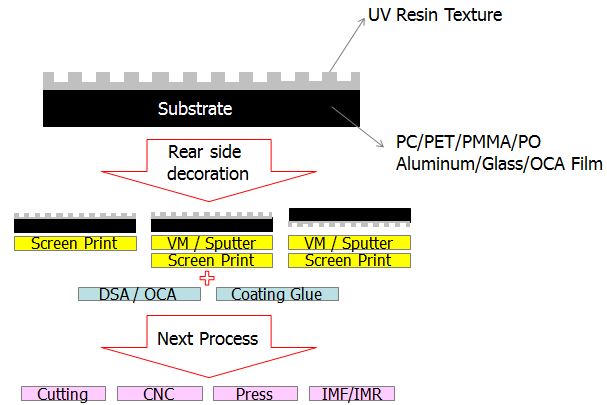

a. PET / PC / PMMA / OCA Film

b. Al / SUS / Copper

c. Glass

d. Others

搭配不同的UV樹脂, 呈現不同的應用效果!

a. HC型: 提供良好的表面硬度與耐磨特性

b. Forming型: 遇熱可以軟化,適合IMD(IML/IMF)產品

c. 染色型: 將色彩混入UV樹脂中,呈現不同的效果

可搭配印刷、鍍膜、沖壓、射出成形、陽極處理、電鍍處理、CNC、IMD/OMD製程!

提供仿真、薄型化、金屬化的效果!

.Different outlooks can be displayed with different UV resists

.UV resist types such as:

a. HC type: It provides well performance on the hardness and abrasion resistance.

b. Forming type: It becomes soft when heat is involved. This is more suitable for IMD (IML/IMF) products.

c. Color type: Colors can be formulated into UV resist in order to perform novel appearances.

.For customers requirements, we also provide

as listed below:

printing, coating, stamping, injection

molding, polishing the anode, electroplating the anod, CNC, IMD/OMD process

.TLO ensures that we produce the products with high fidelity, thinner layer and superb mold to show a strong metallic luster or ideal

surface treatment.