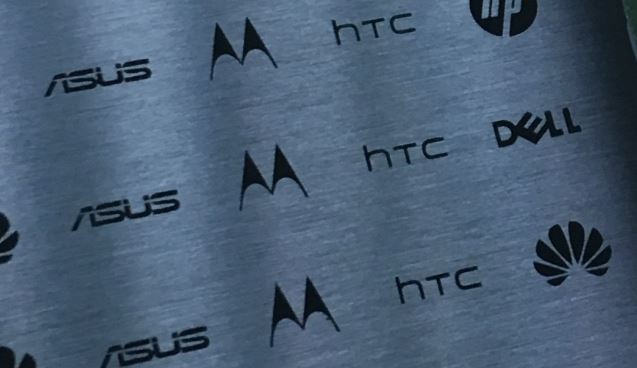

PRODUCTS APPLICATION

應用面廣泛,小至LOGO銘版、零件,大至外觀光學模組。

我們提供具量產性與高質感及合理價格的產品,滿足客戶的需求。

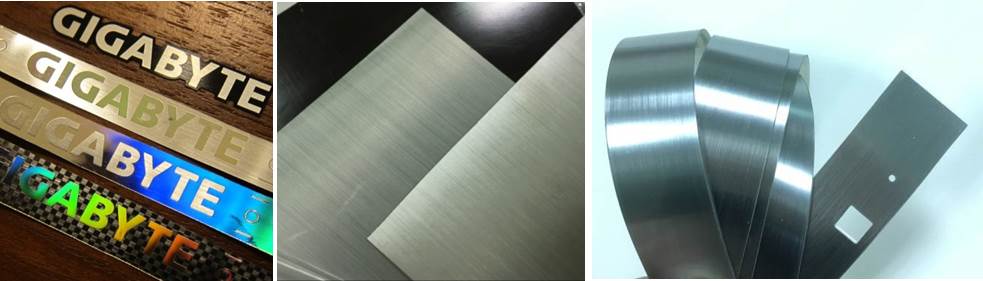

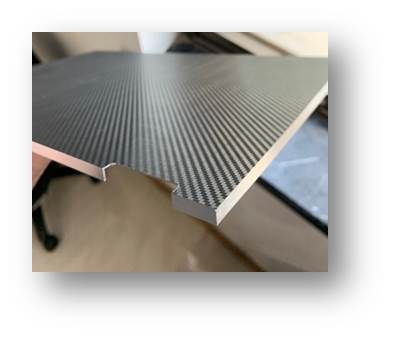

●LOGO

●Name Plate 銘版

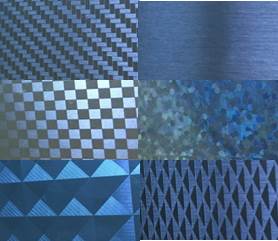

.具有150種公版,拉絲/雷射全像/碳纖/同心圓都可以輕易地製作,當然也可依需求客製化

.PET/PC/PMMA Film 可以金屬化也可以薄型化

.針對不同的需求選用UV膠配方,硬度可以達 6H/1000g,羊毛氈25萬次耐磨耗測試,RCA 300 cycles

.Up to 150 textures. Wire drawing, carbon fiber, concentric circles and other textures can be customized.

.PET/PC/PMMA film can realize the effects of metalization and thinness.

.UV resists are picked based on different requirements. The hardness can stand 6H/1000g. The abrasion test can stand 250,000 times of wool felt; RCA 300 cycles.

●路由器 & 小家電 & mini 投影機

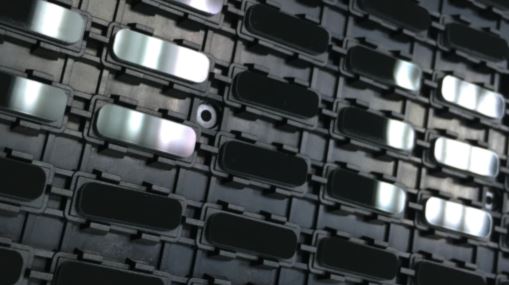

●Finger Sensor Coating (UVPP) 指紋辨識模組外觀處理

.可以在電容式觸控IC載板上直接表面處理,進行色彩與表面HC處理

.HC處理可以同時製作 高光/啞光/拉絲/碳纖紋/LOGO等微結構

.同樣的技術也可以適用於蓋板方案的模組結構

.Colors and hard coating processes can directly applied on the capacitive touch IC flat screen.

.High-gloss, wire drawing, carbon fiber, logo and other micro

structures are able to produce at the same time

.The same technique used to other items

●Name Plate with Light 具光學外觀效果銘版

.使用透明的 PET/PC/PMMA Film 配合印刷與鍍膜製程可以達金屬化效果,我們可以設計特定區塊可以穿透光線,所以當結合LED光源或者背光源,

則可以呈現良好的光學外觀效果

.Materials like transparent PET/PC/PMMA Film could be metalized by the printing and coating manufacturing process.

The transparent areas with a stylish LED backlight could create the perfect optical effect.

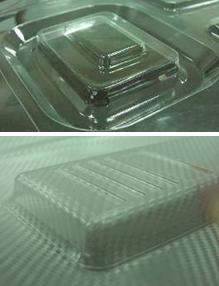

●IMD (In Mold Decoration) 模內射出成型

.IMD是非常環保的製程,依外觀可以分 2D IML & 3D IMF 的產品

.其將所有的顏色與紋路裝飾效果都先於薄膜上完成,再經由 Forming & Trimming製程,後將薄膜置於射出成型模具內,

於射出塑料塡入模穴內時結合成型

.此製程經常應用在 NB的 A件 & Touch Pad 和手機的背蓋、保護殼配件上

.IMD is a eco-friendly process.

.After a plastic film printed with a customer’s design, it is then thermo-formed over a soft tooled mold.Once the plastic decoration is shaped it is trimmed to size. After trimming, the shaped film is placed into an injection mold and a selected mold material is injected behind it forming an integrated bond.

.This manufacturing process is usually used for A parts of NB, TouchPads and Phone cases.

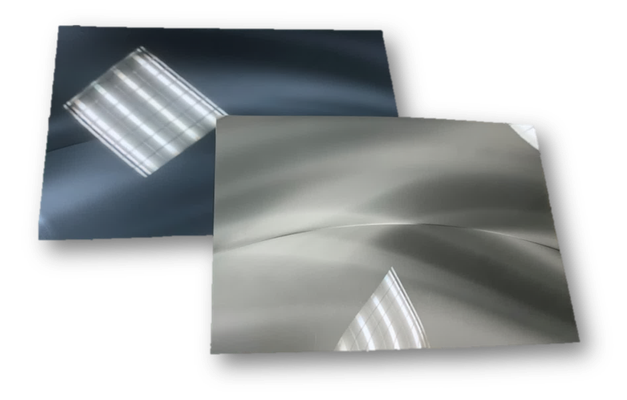

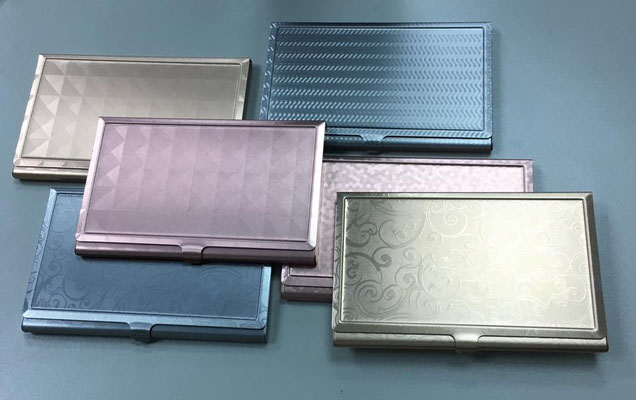

●NIL Application on Metal

.利用NIL技術應用於金屬材料上面,因為傳統上金屬的表面裝飾技術不外乎機械拋光、研磨、噴砂方式及不環保的蝕刻、電鍍、陽極

.NIL可以在同一片金屬材料上呈現多種的表面紋路或複雜的紋路,且於每一次NIL壓印時都能呈現相同的外觀 (一致的拉絲、一致的咬花效果)

.不用機械加工、不用電鍍陽極、不用噴塗金油就能夠生產表面裝飾金屬,想像一下這是多麼的特別

NIL application on metal materials is a more sustainable and easy way to perform complex textures onto a surface with just one single step. Different from the traditional decorations and technologies like polishing, sandblasting and other not environmentally friendly processes like anode dyed, electroplating and etching treatment.

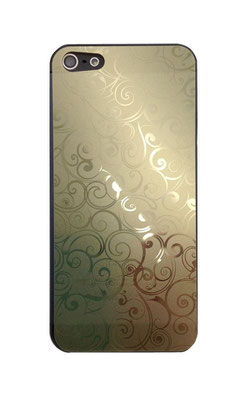

●裝飾防爆膜 Deco Film

.3D玻璃已經引領風潮,但是要在玻璃表面做裝飾加工並不容易,考量在使用手持玻璃產品時避免撞擊與落摔的安全性問題,設計者會在玻璃內側貼上光學級透明 OCA防爆膜,就因如此我們選擇在OCA Film上製作裝飾效果

.用 NIL製程壓印裝飾紋路在 OCA Film上,配合金屬光澤鍍膜與印刷色彩然後將整片膜與玻璃對貼,則可以讓玻璃有特殊的視覺表現

Since 3D glass has been a leading trend, TLO decides to decorate on the OCA film which bonds the back side of glass. NIL not only reduces the risk of damages but enhances the unique visual performance on the glass.

●LED Optical Lens 光學透鏡

.LED為良好的光源,視不同需求經過機構設計、光學模擬、射出模具製造與射出成型,讓整個光學模組可以將 LED點光源改變成面光源或具導光的效果

.可應用於紅外線感應光學讓特定波長可以被控制;直下式電視背光模組燈條透鏡;手機閃光燈透鏡;導光條

NIL has a wide range of applications in various fields including optics.

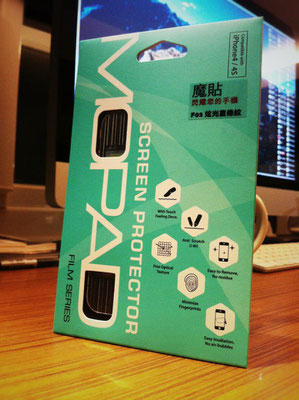

●Accessories

配件

.我們利用 NIL的製程設計產品取代一般的螢幕保護貼與機身保護貼

.在螢幕保護貼上,具有三個特點 a. 精細紋路邊框裝飾 b.螢幕抗眩與抗指紋功能 c.抗眩咬花面可以符合高解析螢幕,不產生 sparkle 不良

.同樣的技術可以應用於 車載顯示器螢幕及中控台

.NIL has also been used on screen protectors. The features of using NIL on screen protectors or console are listed below:

a. multi-texture with high resolution

b. anti-fingerprint and anti-glare functions

c. anti glare coating to keep the high resolution